|

|

||||

Алексей Турбин |

||||

Алексей Игоревич Турбин > Действительный государственный советник РФ третьего класса, кандидат фил. наук, генеральный директор ООО «РАДИОФРОРНТ» Алексей Игоревич Турбин > Действительный государственный советник РФ третьего класса, кандидат фил. наук, генеральный директор ООО «РАДИОФРОРНТ» |

||||

Руслан Егоров |

||||

Руслан Александрович Егоров > Заместитель Генерального директора завода «Электроаппарат», разработчик Системы мониторинга протяженных объектов «ОМЕГА» Руслан Александрович Егоров > Заместитель Генерального директора завода «Электроаппарат», разработчик Системы мониторинга протяженных объектов «ОМЕГА» |

||||

Алексей Турбин Алексей Турбин  Руслан Егоров Руслан Егоров |

||||

ELEKTROAPPARAT COMPLEX WELL MONITORING SYSTEM: Innovative Instrument for Wells Management Decision Making |

||||

|

Abstract: The Bryansk based ELECTROAPPARAT factory

developed a new FOC-based monitoring system for oil and gas

wells. The system can control all procedures in wells doth

on the stage of preparation and on the production stage.

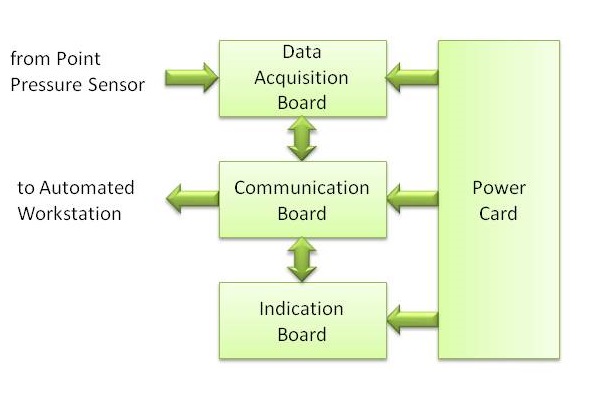

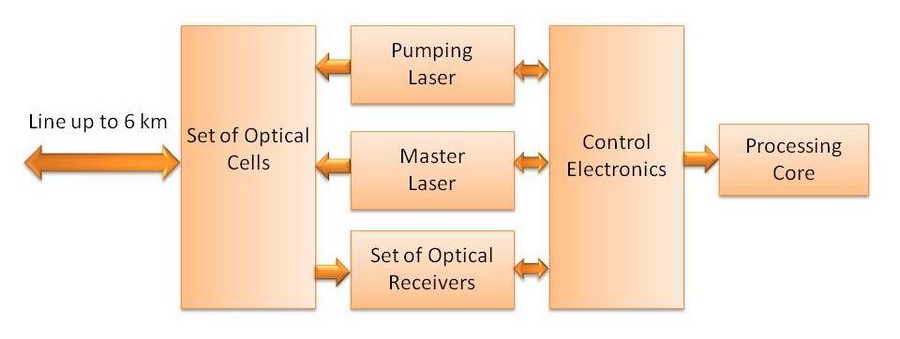

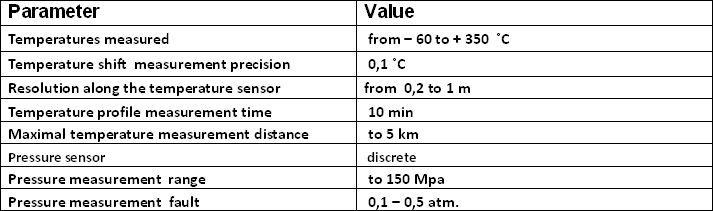

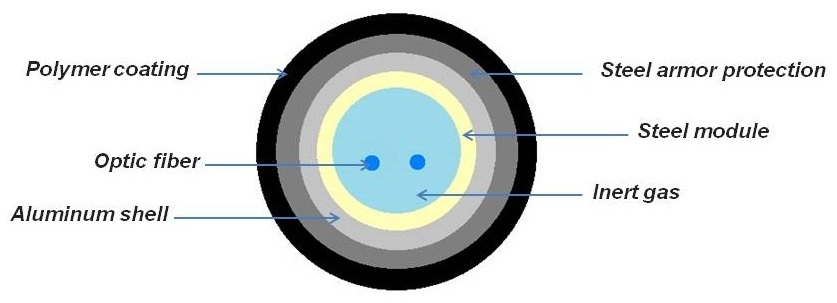

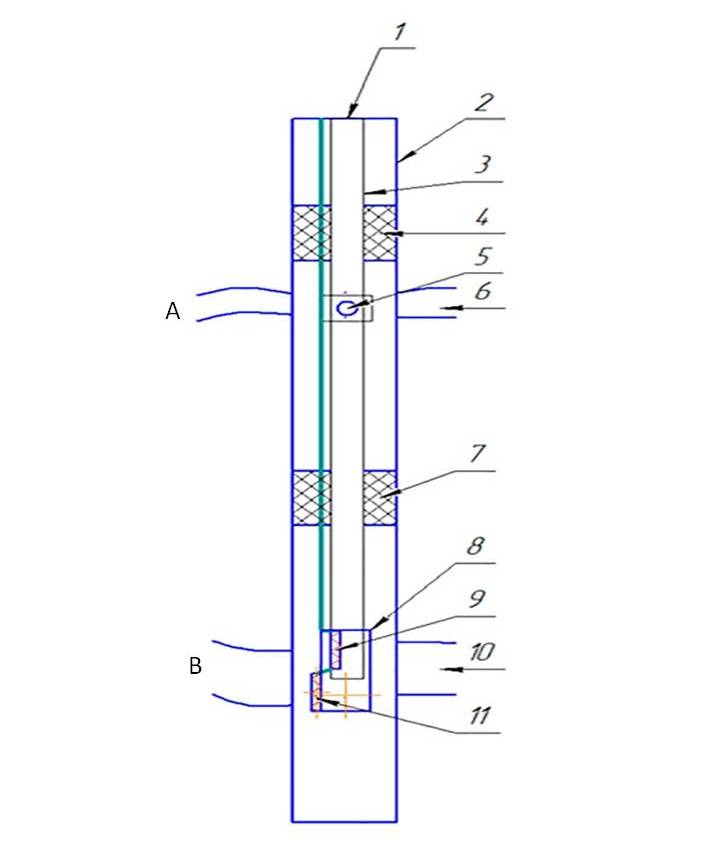

Key words: Oil and gas wells, FOC, leak detection, pipeline security. Relying on the 15 years scientific and practical experience of the OMEGA Company the Bryansk based Elektroapparat Company has developed and prepares for production of the Complex Well Monitoring System (CWMS), the operation of which is based on fiber-optic technologies. The system allows receiving real-time critical information on the well operation which is required for the management of decision making process. CWMS will be offered on markets in 2019. Timely acquisition of crucial information about changes of downhole conditions has fundamental importance for safe and effective technological maintenance of deposit operation. That is why leading international oil and gas companies are promoting the well intellectualization and automation. The introduction of artificial intelligence technologies has marked a new stage in the evolution of well operation. Indeed, there is no possibility of prompt reaction to changes of downhole conditions with a set of equipment based on traditional electrical sensors, though segregation of produced fluid into separate phases (oil, gas and water) occurs mainly after it comes into the hole mouth. According to international practice a smart well consists of three components connected by a logic circuit: a system for obtaining downhole data on the work of both the formations and equipment placed into the well, a fully or partially automated system of decision-making as well as a module of parameters changes in well operation. All necessary information about the well and reservoir is provided by complexes based on fiber-optic technologies: this is the cornerstone laid down by the Elektroapparat Company developers which began researches in this field in early 2000s. In close cooperation with the Transneft Company, world biggest oil and oil products transporter, Elektroapparat created the OMEGA Company through which more than five and a half thousand kilometers of Russian pipelines have been equipped with fibre-optic Leak detection and activity control system (OMEGA LDACS). Fiber optic sensors implemented in CWMS and LDACS are based on the phenomenon of light scattering inside the optical fiber performing the role of both a sensor and a medium for signal transmission. The feature of such sensors recording the scattering is their distribution along a continuous light-guiding core: straylight reflection occurs throughout the fiber, and the reflection from each elementary section determines the state of this area due to temperature or other physical factors. Meanwhile the registration of the reflected signals allows estimating the distribution of temperature or strain along a fiber optical path. Thus, the Optical Time Domain Reflectometry (OTDR) method allows the detecting the temperature either at specified points or continuously along the fiber length. Control and Measuring Complex for Wells Monitoring Constantly improving fiber-optic technologies in the framework of a special research program the developers from Elektroapparat have created a highly sensitive and selective control and measuring complex until recent time based on the application of two distributed sensors: temperature sensor and vibroacoustic fluctuation sensor. Meanwhile the Complex Well Monitoring System presented to the oil and gas community in December 2015 was augmented with a point pressure sensor as well, which has been already launched into a serial production, and a distributed temperature sensor had been adapted for the determination of absolute temperature values. The measurement module of the absolute temperature (MMAT) captures changes of temperature fluctuations along the length of the wellbore in continuous mode.  Figure 1. CWMS pressure measurement module design  Figure 2. CWMS absolute temperature measurement module design The CWMS temperature range varies from -45 to +350°C, and electronic equipment is capable to provide stable operation of distributed temperature sensor measuring absolute temperature at any point along a length of up to 6 km. The mentioned parameters correspond and partially exceed those of systems on the market and are result of long research and practical application: the prototype of CWMS was first implicated on the Ashalchinskoye field in Tatarstan in 2007. CWMS essentially consists of a fiber-optic cable placed in the wellbore, and a logic module, equipped with temperature, vibration and pressure measurement modules, as well as the UPS, providing the system functioning in case of disconnecting the external power supply. Automated workplace of the operator is connected with the CWMS logic module through a local network and can use other monitoring systems at the same time. The PC-based automated workplace displays the results of well monitoring: the event, localization and time. The data are being recorded in a real-time mode along the length of the immersed in the well cable. Table 1. CWMS DATA SHEET  As a sensor CWMS uses a fiber-optic cable developed by the Elektroapparat Company and produced according to Technical Condition 3587-015-51154035-2015. Polymer coating applied for the cable protection is resistant to both high temperature (up to 200°C) and high atmospheric pressure (up to 600 ATM), moreover it withstands aggressive environment with a high content of hydrogen sulphide (H2S) - up to 26%. The use of the same specialized submersible fibre optic cable with multiple optical fibers allows not only to measure temperature, but also to register the acoustic impact along the entire wellbore.  Figure 3. Fiber-optic cable design applied by CWMS Unique Features of Fiber Optic CWMS

Bottom-hole pressure monitoring is carried out with the help of a point pressure sensor placed at the lowest point of the cable. Monitoring the pressure changes in different intervals is possible with the use of multiple (up to 5 on a fiber) detectors. Using three types of sensors allows CWMS improving the event detection accuracy. So decrease in the number of interventions into wells to ascertain causes of operational failures will reduce costs, downtime, as well as maintenance and environmental risks and security threats. One of the examples of the system effectiveness is the leak detection on the production casing in producing well. The undoubted advantage is the ability to research and monitor well operation with complex completions, the design of which does not allow inserting “traditional” GIS devices into the trunk, including additional horizontal wellbores, multilateral wells, and smart wells with controllable equipment and operating devices. It is possible to monitor the temperature field during the well construction, i.e. during the drilling of the barrel and mounting both intermediate and production casings. A fiber optic cable installed in the zone of conductor cementation (in the permafrost zones as well) can perform the quality control function of the column cementing. In this case, local thermal fields which are formed as a result of the endothermic reaction in the process of cement stone formation are recorded. Steady thermal field in the zone of cementation characterizes high quality of cement stone. Low, ragged profile of the thermal field shows the low quality of the cement stone or its absence, which indicates the low quality of the well cementing in general and requires repair works. The Elektroapparat Complex Well Monitoring System will provide:

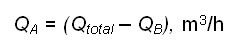

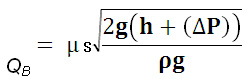

Monitoring of Mechanical Impurities Concentration in Oil, Gas and Water Flow Reverting to the already raised issue of dividing produced fluids into separate phases it should be noted that the content of dissolved gas in oil during deposit exploitation goes towards reduction, though these processes are not immediate, but spread over the whole period of reservoir development. Generally gas cut varies in different productive strata of the same deposit. For the purpose of determining the concentration of gas, oil, water and mechanical impurities in fluid flow, samples are periodically taken from wells. One of the most important issues in the hydrocarbon production is accounting of produced oil and gas. Existing instrument gauges allow determining these parameters of extracted on the surface raw material with great precision. However, according to modern requirements in case of simultaneous operating two or more productive facilities in a well it is necessary to keep separate records for each operated facility. According to the CWMS ideology, if taking the gas content in the period between the borehole researches as a constant value and determining average flux density by Elektroapparat system’s data, then applying the Mendeleev–Klayperon equation the universal gas constant and knowing the temperature inversion it is possible to calculate the concentration of oil, water and mechanical impurities in the flow. This data allow organizing operational accounting in the multiphase flow even taking into account the error of these calculations at the level of 5-10%, which, however, will give adequate information for operational decision-making. Besides during the deposit operation process the information will be automatically accumulated and stored in the archive. These data will allow deducing the interdependence of changes in particular parameters that will eventually help to predict the measurement of phase concentration in the multiphase flow. This information is stored in the electronic module of CWMS, which implements the functionality of the primary data processing and consists of processing core and analog-to-digital converter (ADC). Primary data come from the modules of absolute temperature and pressure.  Figure 4. Pressure sensor calibration process in a laboratory performed by engineer Xenia Bobrova.  Figure 5. The well with two absorbing horizons equipped with CWMS point pressure and temperature sensors. Determining the Acceleration of Intervals Let us consider the most common engineering task to be solved when injecting in disparate horizons (two or more) during reservoir repressuring process management. The task consists of determining the acceleration of each interval separately, when only the total injection rate is known Q, m3/h. For simplicity of explanation let us take the well with two absorbing horizons (Picture 5), equipped with the system of point temperature and pressure sensors, where

As it is seen from the proposed scheme, the well is divided by a packer into two discrete intervals. To solve the problem, it is enough to equip an absorbing horizon with a system of sensors, whereas the intensity of acceleration on the interval (A) will be determined as the difference between total flow rate and the test interval (B).  The main condition under which we can determine the acceleration of the formation is the pressure difference between the tubular (Ptub) and annular (Pan) space. These data are received in real-time mode from sensors 9 and 11, installed in the studied horizon. In addition, to solve this task it is necessary to download several additional parameters in the system:

where:

As all aforementioned parameters except the density are constant values for each well, then it is the only time when it is necessary to download them into the Protocol of automated working place - before the beginning of injection. If during injection the density of liquid is unstable, the system determines it automatically, correcting calculations. Ultimately, to determine injection intensity (speed) is necessary to solve the only formula.  If necessary, similar calculations can be applied for several intervals of pumping, when pre-equipped them with sensors. Ground-based equipment allows you reading information from a group of wells (4 and more) of the reservoir pressure maintenance system, equipped with fiber optic sensors, which facilitates the task of well monitoring in a waterflood system, when a group of wells is injected with the same discharge line. In this case, the system allows determining the injection rate of both defined horizon and each of the wells. The information obtained reduces the time of taking prompt technological decisions and increases the efficiency of reservoir repressuring process management. Conclusion System of complex well monitoring, the creation of which became possible due to the extensive experience of Russian scientists and workers of oil and gas field, even at the stage of elaboration has already aroused an active interest of the Russian oil and gas company representatives. It is envisaged that applying CWMS can lead to the formation of “smart deposits”, the operation of which allows optimizing both equipment efficiency and well productivity, increasing significantly oil production coefficient and reducing not only operating costs but ecological damage. Even not being on the market yet, in 2015 the Elektroapparat system has been presented to Shell specialists as far as on the Moscow session of the BRICS financial Committee on innovations. |

||||

|

||||

|

||||

| Copyright © 2018-2024 Журнал «Вестник Трубопроводных Технологий» (Pipeline Technology Journal) | ||||

|

|

||||