|

|

||||

Алексей Турбин |

||||

Алексей Игоревич Турбин > Действительный государственный советник РФ третьего класса, кандидат фил. наук, генеральный директор ООО «РАДИОФРОРНТ» Алексей Игоревич Турбин > Действительный государственный советник РФ третьего класса, кандидат фил. наук, генеральный директор ООО «РАДИОФРОРНТ» |

||||

Алексей Турбин Алексей Турбин  Boris Gorshkow Boris Gorshkow |

||||

INNOVATIVE RESPONSE TO TECHNOLOGIC AND ANTHROPOGENIC CHALLENGES: OMEGA FOC BASED MONITORING SYSTEM FOR PIPELINES |

||||

|

Abstract: The Moscow based OMEGA Company has developed and

successfully tested a new FOC-based monitoring system for

pipelines. The system can detect both human interference and

leaks with the precision of 2-5 m.

Key words: FOC, leak detection, pipeline security. In April 2010, the state-owned Russian JSC Transneft operating the world largest (appr. 43,000 mi long) oil and oil products pipeline system announced the creation of the OMEGA Company to install the OMEGA developed System of Monitoring of Extended Objects (SMEO) based on Fiber Optic Distributed Sensor System (FODSS) on all newly build pipelines. In February 2011 the OMEGA SMEO was for the first time presented in the United States on the Pipeline Pigging and Integrity Management (PPIM) exhibition and conference in Houston, Texas, in May – on the Pipeline Simulation Interest Group Conference in the Napa Valley. In 2012 the OMEGA SMEO has been presented to participants of the PPIM European round held in Prague The OMEGA DTS

The System provides high-precision detection of location and nature of acoustic vibrations, spatial displacements and temperature characteristics of extended facilities such as pipelines, oil wells, railways, highways, bridges and power lines. The extended object is monitored through the whole length of optic fiber used for the System`s sensor and not requiring electric power along the line in real time mode. The OMEGA DVS

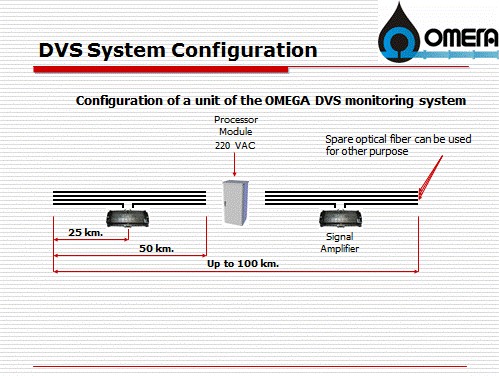

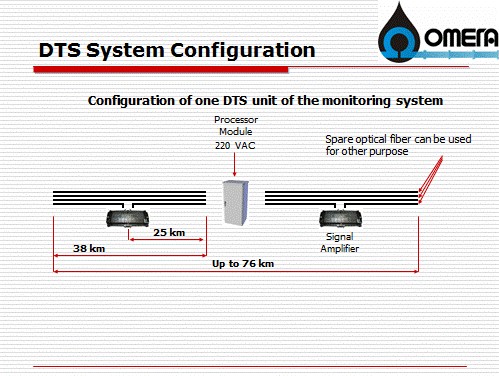

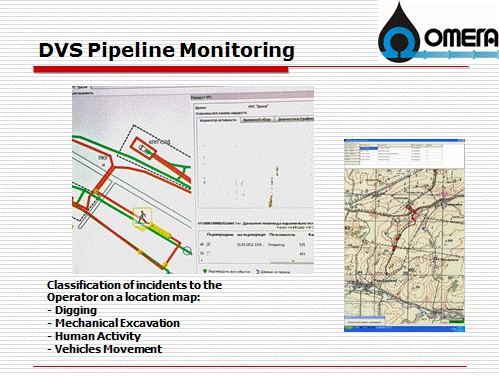

In comparison to similar systems the OMEGA SMEO shows high accuracy (± 5m) both of event detection on extended object and sensor displacement (20 to 30 mm on 6 meter length in any direction). The OMEGA SMEO main option is the on-line monitoring the vibro-acoustic field of the extended facilities. The OMEGA SMEO monitors already a series of Transneft pipelines, in August 2010 the installation of the OMEGA system on the East Siberian Pipeline System built to transport Russian oil to China began.  Monitoring of the temperature field of the extended object provides integrated control over the production and transportation of raw hydrocarbons from the well to the shipment terminal. Since 2006 the OMEGA system is efficiently employed by the OJSC Tatneft, Russia`s 5th rated oil Company, in heavy oil production and steam injection into the well. At the trials conducted in December 2011 the newly developed OMEGA Strains Monitoring Systems of Extended Objects (SMSEO) registered the 20-30 mm bending deformation of a 6 meter long 530 mm pipe. The test results offer the prospect of implementation of the OMEGA SMSEO for instant registration of soil and pipelines sections displacement. To achieve most reliable results the optical cable is placed about 1 m apart from the pipeline body. The FODSS includes a Distributed Temperature Sensor (DTS) and a Distributed Interference Sensor (DIS) as well as SMSEO (optionally). The first is used as leak detection subsystem and can locate oil, gas and other fluids leaks at distances up to 50 km to each side of the allocation of the logical vodule. Space resolution is 2 m and temperature change resolution ~ 0,3 deg.C on 20 min time leg. Leak rate of 2 cubic m per hour can be detected in 1 h after the leak starts. The DIS is used as third party interference (TPI) detector and is based on the principle of phase-sensitive optical time domain reflectometery. Virtual seismic sensors are placed each 5 m. Algorithms used in DIS allow to classify vehicles and various kinds of human activity near the pipeline as well as digging and excavation attempts. The OMEGA SMEO is based on Brillouin Optical Time Domain Reflectometery (BOTDR). The spatial resolution does not exceed 5 m, the stress resolution – 0,01 percent. The time response is of the order of 10 min. To secure best results the SMEO modules (Fig.2) are placed at 50 km distance from each other. At the same time the OMEGA Company keeps developing new possibilities for the System implementation according to demands of several application fields comprising now oil industry and railways. At the same time a series of projects of FODSS implementation on electricity grids and highways are discussed. Using the System`s advantages the OMEGA Company begins it`s expansion on international market. In February of this year a series of field trials on a pipeline near the city of Bryansk in Central Russia for representatives of international oil companies began, the first to visit this site were representatives of the Caspian Pipeline Consortium.  “The fiber optic cable system for remote detection of any hazard impacts and soil compressions along the pipelines is recognized as one of the most advanced engineering developments … The system that consists of a cable network and recording computer hardware was developed in a joint project of U.S. Department of Energy/Gas Technology Institute (Des Plaines, IL) and El Paso Corp., Houston” (1). The extract is quoted from the analytical presentation “The American experience in combating pollution of oil and oil products” by Abalkina, I.L., Korneev, A.V., published by the Institute for the USA and Canada Studies in June 2003 (2). At that time the scientists referred to the valuable international experience and “know-how” in use of fiber optic sensors for the purpose of secure protection of gas and oil delivery systems. Meanwhile, a group of the devotee Russian scientists were conducting then the first field tests of a similar system at the Moscow region testing ground. By now, the system has already been widely used in Russia. What is meant here is the novel development designed by a Russian company “Petrolight”. Now, operating as part of CJSC “OMEGA” (a joint venture with JSC “Transneft”), the company equips every new pipeline constructed by the Russian oil transportation monopoly with the Systems of monitoring extended objects “Omega”, designed by the Russian scientists and named LDAMS (Leak Detection and Activity Monitoring System ) when applied to pipelines. It should be noted that the physics concepts, on the basis of which the systems built around fiber optic sensors are being operated, were discovered decades ago. These sensors have a number of obvious advantages, among which are high sensitivity, excellent extreme temperature performance, achieved, in particular, by installation of specially designed cables, insensibility to electromagnetic fields, electrical inertness, no electrical shock hazards, and fire and explosion safety. Not less important is the corrosion resistance, and as a consequence, considerably long-life operation of fiber optic sensors, multiplexing of homogeneous and heterogeneous sensor data, and not least, a moderate price for the developed systems. When it comes to the product, designed by “Omega”, the undeniable benefit of its SMEO is the most accurate event location equaling 5 meters. Meanwhile many reputable companies can locate the fluid leak on the basis of a detailed data analysis of pressure, flow rate and temperature, with account of the pipeline length, within the accuracy of 50-400 meters. It is, indeed, another qualitative indicator, particularly in view of environmental aspects and with regard to the fact that most pipelines in Russia are buried underground. We should also think of the important “psychological” merit of fiber optic cables as compared with efficient but rather complicated and expensive monitoring systems fitted with video surveillance cameras or satellite communication facilities: there is no much point in protecting a fiber optic line buried along the pipeline against hazardous intrusions. Hence, the range of parameters that can be measured by fiber optic sensors is quite extensive. These are the temperature and temperature change dynamics, absolute and gauge pressure, linear-and-angular movements and the rate of speeding up. The use of high-stable materials and application of cutting-edge technologies make it possible to produce ultra-high accuracy sensors. Thus, technical solutions, applied by the engineers of SMEO, allow to measure pressure with an accuracy up to 0,02-0,03 % at the high end, with temperature effect of 10-3%/С. (3) Apart from the conventional sensors, the sensors of liquid level and phase interface, gas phase composition and others are produced on the basis of fiber optics, being of the utmost interest to oil and gas industries. Recently, distributed sensors of physical properties have been developed on the basis of laboratory researches. In application thereof, optic fiber serves as both a data transmission medium, and a complex of sensors. The main characteristic properties of such sensors are as follows:

The distributed optical sensor is based on reflectometric techniques, similar to that used in a reflectometer, a gauge to measure the loss in optical fibers (4). With high sensitivity command, LDAMS «OMEGA» can be applied for the purpose of detecting pipeline ruptures or small leakages amounting to hundreds of liters per 5 minutes. The fluid flowing under high pressure generates the acoustic wave detected by optic cable. Until recently all this referred solely to the lab or simulated field tests, since the “Omega” Systems are mostly being run along the Russian pipelines. However, on May 15, 2011, the LDAMS «Omega» first time detected the actual fluid leak. (5) It was pinpointed in the course of works for adapting the System to the pipeline LLC “RN-Yuganskneftegas”. The LDAMS detected and identified the fluid leak in 450 meters from GPS in 426 mm Ø low pressure water pipe of the formation pressure maintenance system, running from GPS-1 (a group pumping station) to inventory number 36301071. In addition to the already applied ones science and research departments have developed a detection algorithm of infra low frequency changes, with operating frequency of < 0.1 Hz. Such signals emerge in the System when the temperature changes as a result of sensitive optic cable being heated by hot oil, flowing out of the rupture. The tests proved high probability of detection of the pipeline rupture with the outflow rate up to 10 l/min at a temperature of 25 C. At that, the rupture is detected just a few minutes after the fluid reaches the cable surface. Another major accomplishment of a research scientist group is the completion of development of Brillouin reflectometer to monitor strain generated in pipes of cross-country pipelines, and also their spatial displacements. Strain monitoring will help to track the causes of pipeline deformation, among which are karsts, creeps and soil expansion, which will enable pipeline companies to take immediate action to prevent unrecoverable deformations. This technology is expected to attract not only pipeline operating companies, but also railroad companies, for which the information about deformation of railway embankments is safety critical, the more so, its time history. We would also like to emphasize that distributed fiber optic data measurement systems find ever-widening applications not only in oil transporting, but also in oil extraction fields. Using such sensors enables, within only a few hours, to obtain a number of diagrams of the temperature distributed throughout the well, and to accurately estimate the flow and injection profiles. Moreover, compared with the systems based on point-mode temperature sensors, each reading provides real-time temperature profile throughout the well. In fact, the technology described above, transforms the well into a “smart deposit”, the exploitation of which enables to optimize the machine capacity and enhance the well productivity, and what is more, substantially increase the oil recovery. The physical properties as well as economic calculations make the fiber optic systems effective and applicable in a wide range of different energy fields. Thus, one of the first developed technologies, connected with protection of any patrolled perimeters against unauthorized intrusion, is now becoming more urgent in view of preventing “third parties” from approaching any kind of power stations or pipeline engineering facilities. Furthermore, a project has already been developed to facilitate practical application of SMEO “Omega” to powerline protection, not only against criminal encroachments, but also against excessive powerline icing. Versatility of the detected and processed data, as well as ease of installation and low price for the sensor make SMEO a unique “transformer”, on the basis of which the systems with a spectrum of properties can be tailored to the customers’ needs. Thus, a synergy of the described above functions, provisionally named “smart deposit”, monitoring of closed perimeters and temperature, along with empirical applicability of the “Omega” systems to underwater pipelines, affords to “sum up” the said properties into a high-performance complex designated for secure protection of offshore oil and gas platforms together with the pipeline networks. Speaking about obvious technological benefits of SMEO, and LDAMS in particular, we cannot but mention such an important aspect of their application as environmental friendliness and protection. Actually, by obtaining the timely and precise information on location and nature of a pipeline rupture, the operating company can first thing avoid severe economic losses. Moreover, split oil as well as most transferred fluids, can cause serious, sometimes unrecoverable environmental damage. In fact, using SMEO provides us with a double advantage, I mean that its laying, installing and operating induce no environmental damage. This aspect as well as the company production competence were confirmed by a Competence Certificate “For works which can affect construction safety” granted to “OMEGA” in March 2011; and in May 2011, the specialized Institute of Ministry of Internal Affairs provided the company with a Certificate in respect of all the company products.(6) From now on, all construction, commission and start-up works connected with equipping pipelines and other extended LDAMS objects can be performed independently by the company engineers. The granted certificate applies to installing outdoor electric power lines, mounting, commission and start-up works, and also construction, reconstruction and overhaul. As for the 1st of March of 2012, the fiber optic OMEGA Leak Detection and Activity Control System has been installed on appr. 4.000 km of the “Transneft” pipelines. Meanwhile new functions of OMEGA Systems are developed, and the first to mention is the OMEGA Pig Tracking Function first introduced at the PPIM-2012 in Houston. Passing through the pipeline, pigs come across the welded connections, where they create some disturbances in the form of pressure waves propagating in both directions with the speed of the sound in the liquid. Each disturbance of such matter creates λ-shaped waves recorded by the chart recorder. The angle of the wave is determined by its speed in the pipe (about 1050 m/sec) and the length of the tracks depends on its attenuation, as well as the sensitivity of the OMEGA System.  In some cases, the OMEGA Monitoring System captures the pressure waves generated by the movement of the inspection tool from the distance up to 30 km. The picture shows λ-shaped waves indicating the movement of five pigs simultaneously (Fig. 4). Another possibility examined now at the Transneft operated Baltic Pipeline System - 2 where the OMEGA Monitoring System has been commissioned in November 2011 is the registration of pressure waves. The OMEGA SMEO registers and identifies pressure jumps resulting from changes in operating conditions of the pipeline. On fig. 3 there are two such jumps propagating on the “Transneft” BTS-2 pipeline from the pumping station Unecha in direction of Andreapol (the distance exceeds 500 km). The disturbance propagation speed calculated on the basis of the tracks attenuation angles equals to 1050 m/sec. The mentioned trials on the BTS-2 showed another option especially interesting for the security aspect of the pipeline monitoring. The OMEGA System sensitivity permits to track the location of a helicopter patrolling a Transneft pipeline on low height. The OMEGA System allows to determine the flight speed equaling in this case 140 to 160 km/h. One of the options of the OMEGA Systems being under trials now is the detection of gas leaks in different conditions inclusive off-shore locations and permafrost areas. This function is among the OMEGA possibilities most required on international markets which is confirmed by our internationally respected partners preparing to implement the OMEGA System on oil and gas pipelines. Reference Index

|

||||

|

||||

|

||||

| Copyright © 2018-2024 Журнал «Вестник Трубопроводных Технологий» (Pipeline Technology Journal) | ||||

|

|

||||